CMS TECNOCUT WATERSPEEDY S

WATERJET CUTTING SYSTEM

Tecnocut Waterspeedy S is a waterjet machine designed specifically for high-speed machining of plastics and composites. It offers exceptional motion dynamics to ensure high productivity. Ideal for cutting flexible materials such as plastics, foams, rubbers, composites, laminated materials, industrial gaskets and engineered materials. The advanced design of its structures, which is the result of continuous investment in research and development, and the sophisticated technological solutions adopted ensure long-term precision, speed and flexibility to guarantee an exceptional degree of finish and unparalleled accuracy.

• Very high dynamics coupled with the ability to work with multiple cutting heads ensure very high productivity and competitive costs compared with conventional cutting systems.

• Loading/unloading in hidden time using a built-in automatic pallet changing system

• large work areas for maximum production freedom

• the compact design allows handling and transport without removing any mechanical parts, ensuring reduced recommissioning times

• Dedicated programming system for optimized cutting path generation. Based on interactive software with a touchscreen for management of all CNC functions. The cutting program can be created from the built-in software or from a DXF file to minimize the cycle time.

Advantages

NO ONE IS AS FAST IN WATERJET CUTTING

Racks and helical pinions ensure unparalleled performance with fast speeds of 70 m/min and accelerations of 7 m/s2.

PRODUCTIVITY INCREASE UP TO 85%

Cutting configuration with from 3 to 7 pure waterjet heads with 3-axes and NC-controlled automatic spacing, to meet production requirements related to machining nesting of foam sheets and rolls.

CUTTING ZONE PROTECTION FOR A CLEAN AND QUIET ENVIRONMENT

Soundproof cabin to protect the cutting area and to prevent any contact with moving mechanical parts and leakage of water and dust.

NO-STOP CUT: ELIMINATION OF DOWNTIME FOR LOADING AND UNLOADING

Separate loading and unloading zones with servo motor for automatic pallet handling to eliminate loading and unloading downtime. Both pallets have a stainless steel honeycomb top.

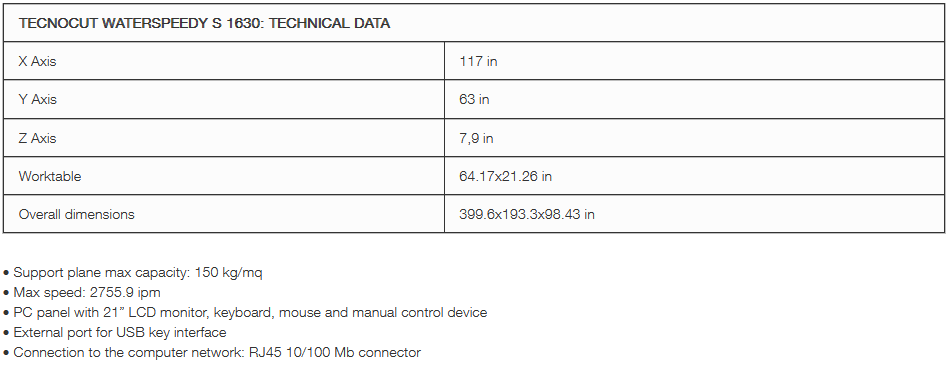

Technical Data