CMS Kreator

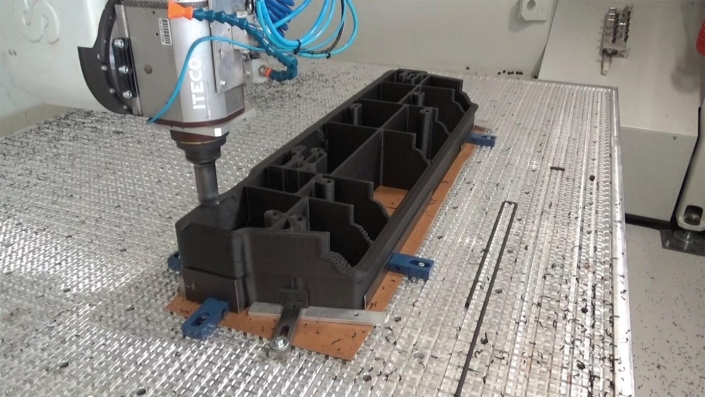

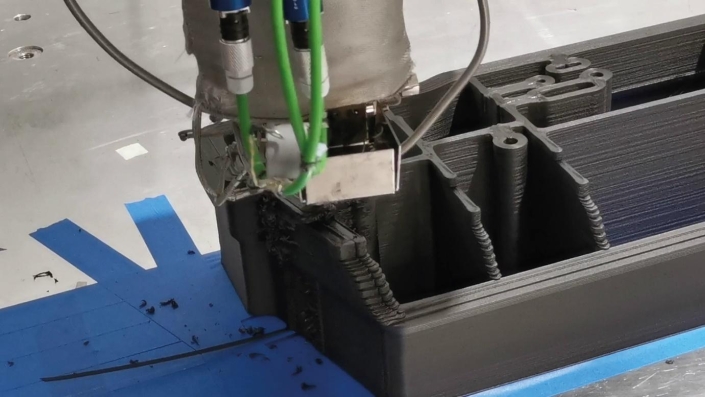

Hybrid system for additive manufacturing and milling: Making Additive Real

CMS Advanced Materials Technology, leader in CNC machines for composite processing, started in 2018, in cooperation with the prestigious german Fraunhofer Institut, to develop an original LFAM (Large Format Additive Manufacturing) solution, for improving the competitiveness of composite and other industries.

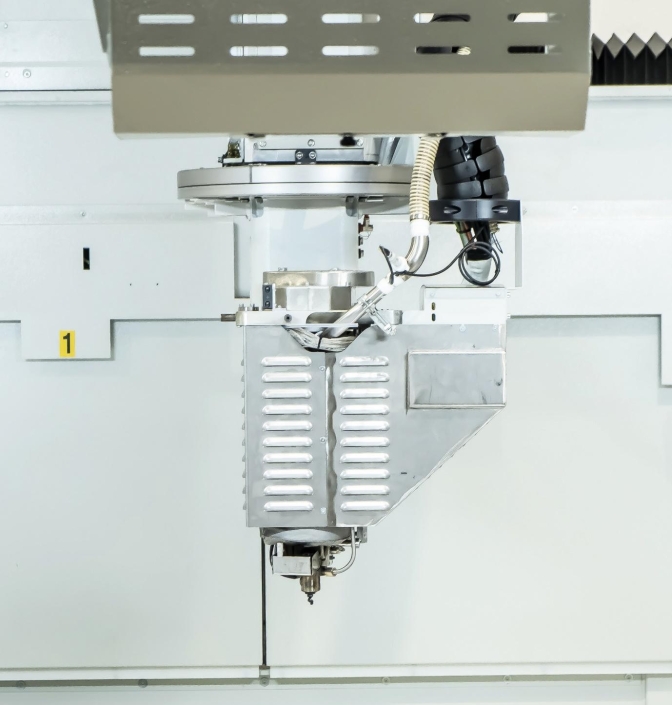

The Additive Manufacturing technology adopted is Screw Extrusion Additive Manufacturing (SEAM)

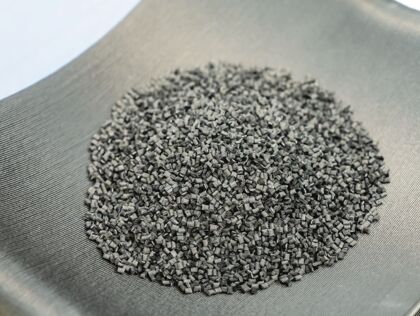

- Thermoplastic polymer, in granulated form is the material used.

- The polymer is almost always reinforced (discontinuous fibres of carbon or glass) and the reinforcement is inside the granules.

- The extrusion is done by a single screw extruder that melts the granules.

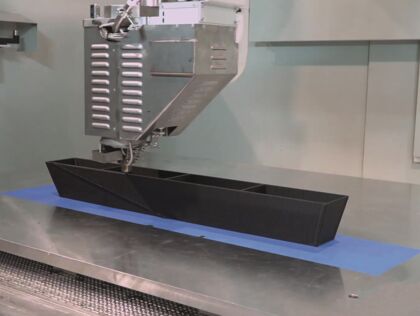

- The extruder is moved by the tool machine’s axes.

- The melted polymer exiting the extruder is deposited in layers that plasticize and form a single piece.

Advantages

HIGH FLEXIBILITY

The CMS kreator technology allows for 45° and 90° printing. The CMS kreator technology permits the use of different kinds of materials: PA, PP, PESU, PEI, PET, ABS, AIRTECH DAHLTRAM, and much more.

MATERIAL SAVING

At least 81% material saving for manufacturing a part, compared to current manufacturing technologies and competitors.

SUSTAINABLE SOLUTION

Printing speed up to 16 m/min, faster than large sized FDM and competitors.