CMS Ethos K

5 axes high speed CNC machining center with monobloc structure

This is the most compact machining center of the Ethos serie. The monobloc system provides the stability, accuracy and high machining quality even under the presence of heavy stresses. The compact dimensions allow easy fitting to every productive environment, whilst providing a large work envelope.

- mechanical moving parts designed to optimize the power/weight ratio, driven by high-performance motors with high speed and acceleration characteristics

- high operating power, geometric accuracy and machining reliability

- maximum accessibility to the working area for an easier loading/unloading, even for heavy parts

Advantages

PRECISION LIKE NEVER BEFORE

Thanks to Aero-Design technology, the frames of the machining centre boast structural rigidity up to 23% higher than the average in its category, with a high capacity of vibration absorption. In addition, recirculating roller guides and zero backlash kinematics allow the achievement of unprecedented accuracies on such types of machining centres. The combination with state of the art acceleration and speed ensures, as a result, the perfect balance between precision and speed for the most demanding productions such as automotive and aerospace

POWER AND CONTROL

ethos k can be fitted with an innovative 5-axis operating unit equipped with torque motors on the rotating axes; this technology allows direct coupling between the motors and the axes, eliminating all the transmission components and therefore all inaccuracies and mechanical wear; the torque motors can also reach accelerations and speeds up to 5 times higher than traditional solutions while ensuring 41% higher precision.

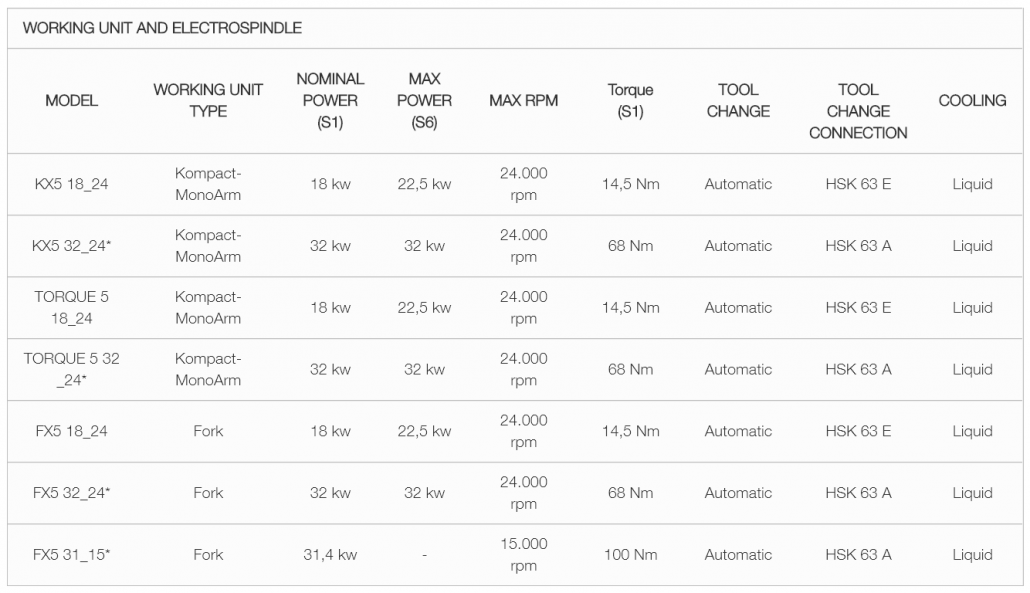

Ethos K also features high-performance electrospindles with powers up to 32kW/S1 and torque up to 100 Nm.

TOOL CHANGE IN A FLASH

ethos k is equipped with a high speed automatic tool changing system with 48-station chain magazine and exchange lever: all the tools you need in no downtime.

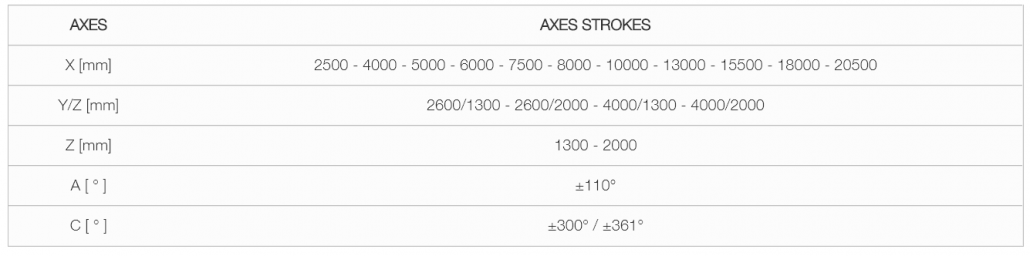

Technical Data