CMS Br5cs

In-line thermoforming

The br5cs series has high productivity features and fully automatic operation with no operator intervention required. On the br5cs the loading-forming-unloading is carried out in-line.

- high quality and large production quantities

- possibility to form both with positive and negative moulds

- safe and fast mould change

- preheating system: increases the capacity of the machine, avoids thermal shock and allows high quality thermoforming, even with difficult plastic materials, in a high productivity environment

- dimensions of 1.500×1.000 mm up to a 2.500×1.600 mm

Advantages

THERMOFORMING: CMS MADE IT EASIER!

Simple management of all process parameters thanks to a userfriendly software specifically developed for thermoforming process.

It shortens by 53% learning times compared to different solutions using wizard procedures. All variables are saved in a single program ensuring the same results even after years.

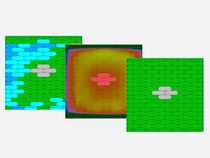

THE UNIQUE * SOLUTION FOR HEATING MANAGEMENT THAT ONLY CMS CAN OFFER (*PATENTED)

Smart heating control advanced system using thermal vision thanks to the exclusive ThermoProphet by CMS. Thermal image allows to read surface temperature and through this information apply modifications to heating percentages automatically. This allow to ensure maximum heating quality even with every kind of environmental conditions. Thanks to this is possible to reduce probability of bad parts by 55% end restart time by 25%

IT’S NOT ONLY EASIER, IT IS ALSO FASTER

Productivity values 33% higher than the market’ standard thanks to pre-heating station which reduce significantly cycle time. By using a double (upper and lower) pre-heating system is possible to start heating up material while forming and cooling the previous piece. This will also reduce thermal shock given to plastic material.

THE ACCURACY YOU HAVE BEEN LOOKING FOR

“In line” machine design with toothed chain transportation system. Sheets are centered automatically and moved quickly in forming station. The formed part is unloaded while hanging by the edges without touching the shaped part. This feature is teh optimal solution for pieces with important negative drawing.

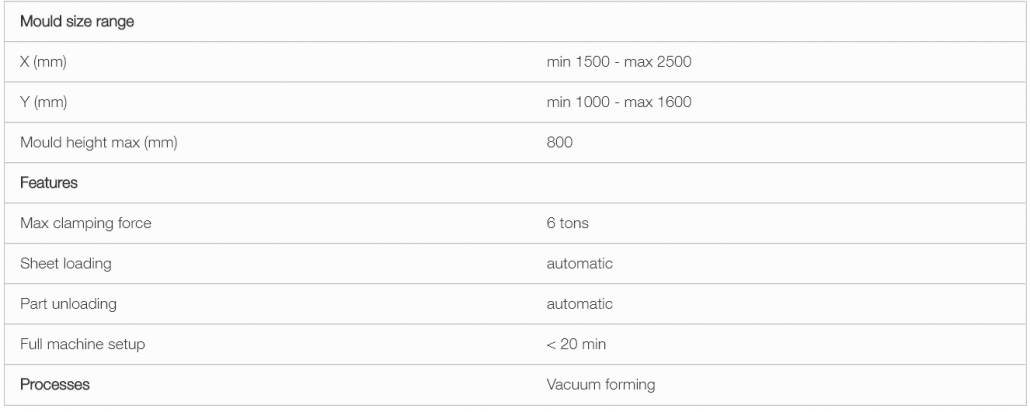

Technical Data