CMS Antares

5-axis high speed CNC machining center with monobloc structure

Its compact design easily fits into any production environment, while still benefitting from the large working envelope.

The monobloc structure ensures stiffness and accuracy throughout its lifetime.

Maximum accessibility to the working area for piece loading / unloading by manual or automated systems.

Full acoustically-lined enclosure to contain dust and to reduce the noise generated by the machining operation.

Available also with rotating table (TR).

Advantages

PRODUCE MORE AND BETTER: TODAY AND TOMORROW

The advanced design of the structure, a result of CMS’ research center, and the technical solutions adopted guarantee rigidity and precision over time so that the high finish and accuracy of the workpieces remains a constant feature of your production over the years. The accuracy of ANTARES CMS boasts the industry’s best-in-class performance in its category: +23% machining precision and accuracy.

FLEXIBILITY THAT COUNTS

The compact dimensions, with overall dimensions that are up to 11% smaller in its class, allow an easy and cost-effective installation in any production context; at the same time the wide working volume available does not limit the size of the workpieces.

DUST? NO PROBLEM!

The machine has been designed to better manage dust, chips and noise produced during machining. The total enclosure and the outfit of a wide range of accessories and systems expressly designed for the various types of materials and productions ensures the safety of the operators, cleanliness of the working environment and production efficiency.

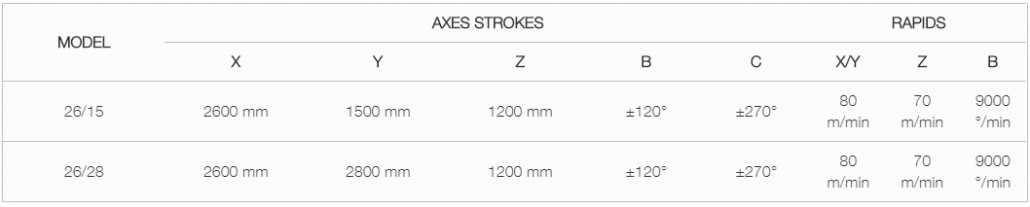

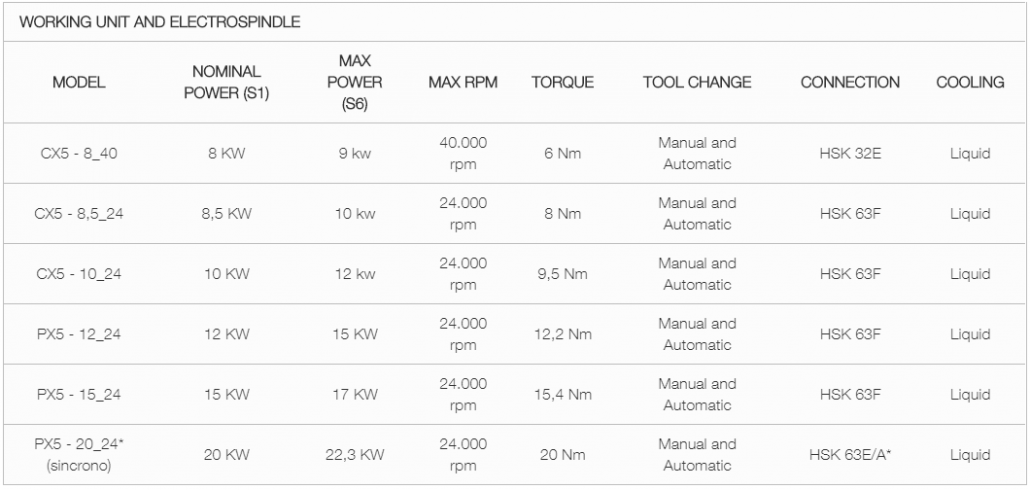

Technical Data

* HSK63A available only for controlled spindle